DO-254 Interview Questions

Are you looking for a DO-254 interview question for an upcoming job interview? Then, you have landed at the right place.

I have spent many hours compiling these Top DO-254 interview questions.

I have tried to create the top collection of DO-254 interview questions. These DO-254 interview questions are being asked in any of the top aerospace MNCs.

I hope this article will be helpful for your upcoming interview. This could definitely you learn something new.

If you think I have missed some aspects of the DO-254 interview questions, please write in the comment box. I will definitely try to address those in the future so that It could be helpful for others.

All the best for your DO-254 interview!

Q1) What is DO-254?

DO-254 is a guideline document that provides guidance for design assurance of airborne electronic hardware. So, in simple words, DO-254 is a process-oriented safety guideline document used for developing electronic hardware equipment for commercial aircraft.

DO-254 is also known as DO254, D0254, and Eurocae ED-80.

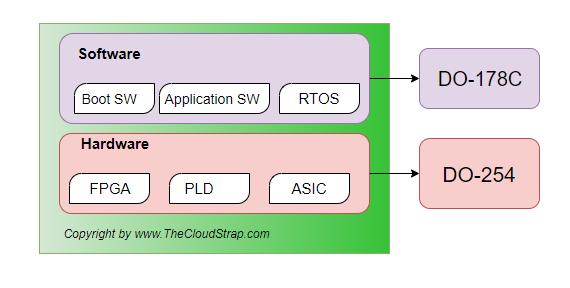

The original idea was to create two safety guidelines – one for commercial airborne software and another one for commercial airborne hardware. DO-178C or ED-12C is for software development guideline documents, whereas DO-254 is for hardware development guideline documents for the aviation community.

The actual title for the DO-254 is Design Assurance of Airborne Electronic Hardware.

The “DO” stands for “Document” and 254 is the serial number of the document assigned by RTCA.

The main focus of this document is to establish a set of guidelines in the commercial aviation industry for building safety-critical hardware. The aviation industry and certification authorities – such as the Federal Aviation Administration (FAA), European Aviation Safety Agency (EASA), Transport Canada, Japan Civil Aviation Bureau (JCAB), Civil Aviation Authority (CAA) etc) have been using this document to approve the hardware for airborne systems.

In the United States, the FAA (Federal Aviation Administration) mandates DO-254 for complex electronic hardware such as FPGA, ASIC, etc. The equivalent standard in Europe is EUROCAE ED-80.

Nowadays, most aviation products contain complex electronic hardware that requires following DO-254, mandated by certification authorities such as FAA, EASA, etc.

Q2) What was the motivation for creating DO-254?

DO-254 was created mainly for two reasons:

- The aviation hardware development process was unregulated in the early 60’s or 70’s. Do-254 came into the picture to address the safety perspective of aviation hardware.

- Using electronics, the firmware was getting popular in commercial aircraft and DO-254 was put in place to regulate the process and safety.

Q3) What are the benefits of DO-254?

Nowadays, most of the avionics projects follow DO-254 as a standard for developing hardware that will be used in commercial aircraft. DO-254 ensures the safety of the hardware, verifiability of the hardware, and higher reliability and consistency.

Q4) What is the scope of DO-254?

As we have discussed previously, the DO-254 was created mainly to regulate the avionics hardware development for commercial aircraft. More specifically, it is used for developing complex electronic hardware.

For simpler hardware, the DO-254 is not required to follow, unless and until the certification authority wants the applicant to follow it. Following the Do-254 process for simpler hardware would definitely add up the extra project cost and add little value. The following image clearly shows the scope of DO-254:

Q5) What is the DO-254 Design Assurance level or criticality level?

In view of the safety criticality, various parts of the aircraft system are assigned different Design Assurance Levels.

A highly safety-critical system would receive a higher DAL (DAL-A is the highest critical level and DAL-E is the least critical). The System Safety Assessment Process (SSAP) will determine the safety criticality of the system.

The DO-254 criticality level is determined based on the failure contribution of a hardware failure. For example, if a DO-254 hardware failure leads to a failure condition of DAL-A, then the particular hardware is assigned a criticality of Level-A.

Every avionics LRU will have different criticality levels based on their failure contribution to the overall aircraft system.

Q6) What are failure condition categories as per DO-254?

There are a total of five failure conditions identified by the DO-254 document:

- Catastrophic: Catastrophic failure condition which indicates the loss of life and aircraft.

Examples – Engine Control Software, Flight Control Software (FCS), etc.

- Hazardous: Hazardous condition indicates a small fatal injury and increased workload to the flight crew.

Examples – Cabin Air Pressurization Control Software, Primary Flight Display (PFD) Software, etc.

- Major: Failure condition which would reduce the functional Capabilities of the aircraft and increase the workload of the flight crew and comfort level of passengers.

Example – Cargo Air Conditioning System (CACS).

- Minor: A little increase in crew workload but manageable and discomfort to the passengers.

Examples – Flight Entertainment Systems (FES), Transponders and Communication System Software, etc.

- No Effect: No effect at all on the operation of the aircraft.

Example – Satellite Phones, Vending Machine

Q7) What is DO-254 Level-A?

The DO-254 Level-A hardware is hardware whose anomalous behavior will contribute to the Catastrophic failure condition for the aircraft.

Q8) What is DO-254 Level-B?

The DO-254 Level-B hardware is hardware whose anomalous behavior will contribute to the Hazardous failure condition for the aircraft.

Q9) What is DO-254 Level-C?

The DO-254 Level-C hardware is hardware whose anomalous behavior will contribute to the Major failure condition for the aircraft.

Q10) What is DO-254 Level-D?

The DO-254 Level-D hardware is hardware whose anomalous behavior will contribute to the Minor failure condition for the aircraft.

Q11) What is DO-254 Level-E?

The DO-254 Level-E hardware is hardware whose anomalous behavior will contribute to the No-Effect failure condition for the aircraft.

Q12) What is the DO-254 Planning Process?

The DO-254 planning process is very critical in the context of project certification. It is a very important/key document to set up the planning for the whole project. The DO-254 planning process shall have the following objectives:

- Hardware Process Activities should be defined.

- Hardware Development Standards should be defined.

- Hardware Life Cycle, Environment, Methods, and Tools should be finalized.

- Hardware Life Cycle Process transition criteria and feedback mechanism should be established.

When an organization does not pay attention/give importance to the planning phase that’s why they tend to struggle to certify their product at the end.

Q13) What are the deliverables of the DO-254 Planning Process?

The DO-254 planning process shall have the following deliverables or output:

- Plan for Hardware Aspects of Certification (PHAC)

- Hardware Development Plan (HDP)

- Hardware Process Assurance Plan (HPAP)

- Hardware Configuration Management Plan (HCMP)

- Hardware Verification & Validation Plan (HV&VP)

- Hardware Requirements Standard

- Hardware Design Standard

- Hardware Architecture Standard

- Hardware V&V Standard

Q14) What is PHAC in DO-254?

The DO-254 PHAC (Plan for Hardware Aspects of Certification) document is a key document in the process of hardware certification. It is the primary document that lays the foundation of the avionics hardware development planning.

The DO-254 PHAC document is mainly used to describe the overall system overview, hardware characteristics, certification considerations, life cycles and life cycle data, and hardware development schedule.

Q15) Does hardware, like the DO-178C, need both high-level and low-level requirements?

As per DO-254 document, the hardware requires only one level of requirement.

However, the DO-254 mandates to have two levels of design: Conceptual Design and Detailed Design.

Q16) What is DO-254 requirement traceability?

DO-254 suggests having bi-directional traceability. Therefore, requirement traceability should be performed in both the approach – Top-Down approach and the Bottom-Up approach. Also, requirement traceability could be the one-to-many or many-to-one relationship.

The Top-Down requirement traceability ensures that the hardware requirements are traced to conceptual design and detailed design and also hardware requirements to test. This ensures that all the requirements have the corresponding conceptual design, detailed design and test cases and procedures.

On the other hand, the Bottom-Up requirement traceability (Implementation to Design, Design to Requirements, Test to Requirements) ensures that the implementation, design, and tests are in place to implement and verify the requirements.

The trace data should also explain the partial coverage. For example, if a particular test only verifies some part of a requirement, the verification traceability should have a mechanism to explain the partial coverage.

Q17) What is DO-154 Independence?

As per DO-254, Independence is required during the verification process, meaning that an independent person is required to perform the verification activity such as test, review, etc.

The hardware designer, who has developed the conceptual design or detailed design, cannot perform the verification activity.

The Independence levels are determined by the design assurance level (DAL) associated with the hardware product.

The Independence matrix could be maintained manually or by an automated tool.

Q18) Can you explain what is major DO-254 certification risks?

There are several certification risks that an organization could face (especially an organization that is new in aviation industry):

- Not appreciating the importance of great planning

- Poor attention to verification life cycle data

- Not realizing the impact of effective requirement writing

- Ambiguous DO-254 hardware requirements

- Not enough coordination with the certification authority

- Missing DO-254 traceability

- Inadequate Do-254 independence in the review process

- Inadequate DO-254 checklists

- Insufficient coverage

- Delaying the SOI audit

Q19) What is DO-254 Tool Qualification?

Many tools, including design tools, implementation generation tools, simulation, test tools, and structural coverage tools, are needed for hardware design, development, and verification.

As per DO-154, such tools are needed to be qualified to gain confidence in the output of the tool.

Q20) What is DO-254 added cost?

Following the DO-254 definitely adds extra cost to the project. Based on the industry survey, by and large, there could be a 50-250% additional cost to follow the DO-254 guidelines and meet the DO-254 objectives.

However, the added cost may be reduced significantly for a mature organization with a long history of delivering and certifying DO-254 hardware.

On average, an aviation project meeting DO-254 guidelines can cost 2.5x to 5x more than the same project without the DO-254 process.

One of the main reasons for having the cost shoot up to 5x level is the lack of DO-254 knowledge and experience, especially in the newer organization.

Q21) What are the documents required to submit to FAA/EASA?

The following documents are needed to submit to the certification authority to certify the DO-254 hardware:

- Plan for Hardware Aspects of Certification (PHAC)

- Hardware Verification Plan (HVP)

- Hardware Accomplishment Summary (HAS)

- Conceptual Design (Top Level Drawing)

Q22) What is the Hardware Design Process as per DO-254?

Here are the process steps for the Hardware Design Process in DO-254:

- Requirements Capture

- Conceptual Design

- Detailed Design

- Implementation

- Verification

- Transfer the design to production

Conclusion:

DO-254 is a very important guideline document for any hardware that is being developed for commercial aircraft. I have tried to cover most of the DO-254 questions that you can face during the interview.

However, if I missed any topic or area in the context of DO-254 interview questions, please feel free to comment below.

You can also contact me directly: admin [ at ] TheCloudStrap { dot } com

Note: I have also compiled all the DO178C tables in one document along with the explanation and created a pdf copy of it.

If you want to get the FREE PDF copy, please leave your email ID in the below comment box, and I will send you the copy. This document would definitely give you a far better understanding of the DO178C objectives.

Hopefully, this article could help you!

Good luck with your interview.

Cheers!

This post was published by Admin.

Email: admin@TheCloudStrap.Com